齒輪加工原理,常見(jiàn)的有兩種,仿形加工和范成加工。

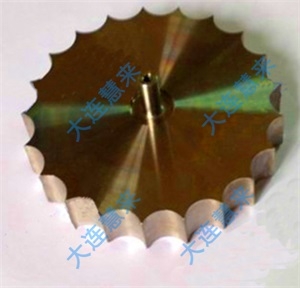

1、仿形加方法:齒輪加工刀具切出齒輪的齒槽,刀具的“截面形狀”是齒輪齒槽的形狀。大連精密零部件加工齒輪時(shí),沒(méi)有齒輪嚙合運(yùn)動(dòng),加工出來(lái)的齒輪精度低,一般精度在11級(jí)以下;

2、范成加工方法:齒輪加工刀具本身就是“齒輪或齒條”,齒輪滾刀可以“認(rèn)為”是齒條,屬于齒條類型刀具。加工時(shí),齒輪刀具與被加工齒輪之間有“齒輪嚙合”運(yùn)動(dòng)。齒輪刀具齒廓刀刃,運(yùn)動(dòng)包絡(luò)出被加工齒輪的齒廓、齒面,是理想的漸開(kāi)線,加工精度較高,常見(jiàn)的有,滾齒、插齒、剃齒屬于精加工。

There are two common principles of gear machining: profile machining and profile machining.

1. Imitation method: The gear machining tool cuts out the tooth groove of the gear, and the "cross-sectional shape" of the tool is the shape of the gear tooth groove. When processing gears with precision components in Dalian, there is no gear meshing motion, resulting in low precision of the processed gears, generally below level 11;

2. Fan Cheng's machining method: The gear machining tool itself is a "gear or rack", and the gear rolling cutter can be "regarded" as a rack, belonging to the rack type tool. During processing, there is a "gear meshing" motion between the gear cutting tool and the processed gear. Gear cutting tools have tooth profiles and cutting edges that envelop the tooth profile and tooth surface of the processed gear. They are ideal involutes with high machining accuracy, commonly used in precision machining such as gear hobbing, gear hobbing, and gear shaving.