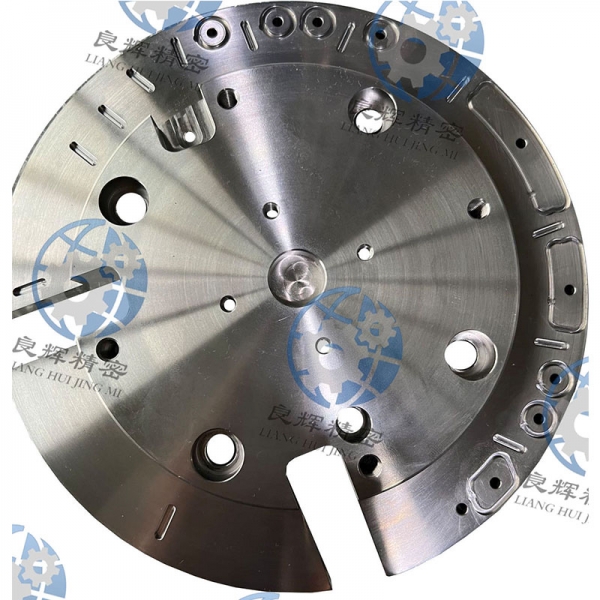

精拋:用以加工軸或孔類零件。這類零件大部分采用淬軟鋼,有很高的強(qiáng)度。大連精密零部件加工大部分高精度機(jī)床主軸采用負(fù)壓或動(dòng)壓液態(tài)滾動(dòng)軸承,以確保高穩(wěn)定性。切削的極限精度除受車床主軸和床體彎曲剛度的危害外,還與沙輪片的挑選和均衡、產(chǎn)品工件核心孔的加工精度等原因相關(guān)。

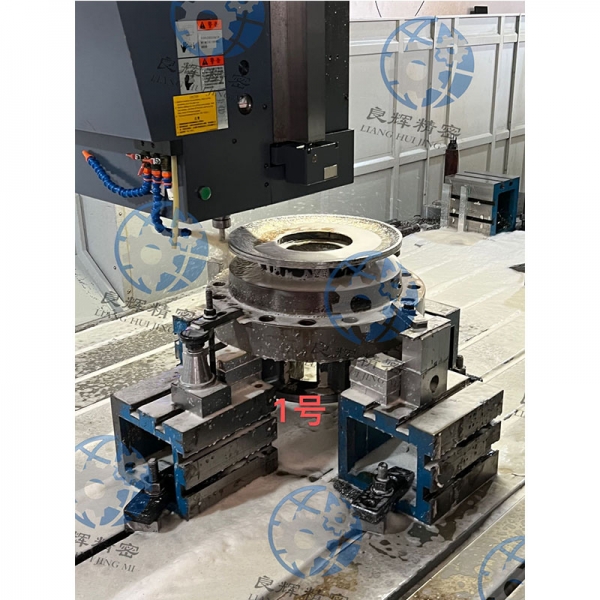

碾磨:運(yùn)用相互配合件互研的基本原理對(duì)被加工表層上不規(guī)范的突起位置開展挑選加工。磨砂顆粒直徑、切削速度和鉆削熱均可精l確操縱,因而是高精密加工技術(shù)性中得到高精度的加工方式。

Precision polishing: used for machining shaft or hole parts. Most of these parts are made of quenched and tempered steel, which has high strength. Most high-precision machine tool spindles in Dalian's precision parts processing use negative pressure or dynamic pressure liquid rolling bearings to ensure high stability. The ultimate precision of cutting is not only affected by the bending stiffness of the lathe spindle and bed body, but also by the selection and balance of the sand wheel, the machining accuracy of the core hole of the product workpiece, and other factors.

Grinding: Using the basic principle of mutual cooperation and research, select and process irregular protrusions on the surface to be processed. The diameter of abrasive particles, cutting speed, and drilling heat can all be precisely controlled, making it a high-precision machining method in high-precision machining technology.