用于密封作用的泵用零件

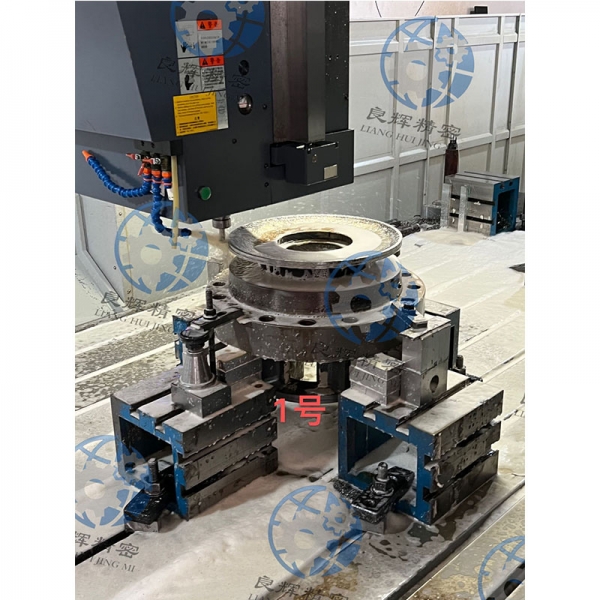

泵用零件是指用于泵設(shè)備維護(hù)和維修的零部件,對(duì)于泵的正常運(yùn)轉(zhuǎn)和性能發(fā)揮起著關(guān)鍵作用。泵用零件廣泛應(yīng)用在各種工業(yè)領(lǐng)域,包括化工、石油、造紙、電力、冶金、礦山等行業(yè)。泵用零件種類繁多,包括泵體、葉輪、軸承、機(jī)械密封、軸套、軸、機(jī)殼等。大連機(jī)械加工

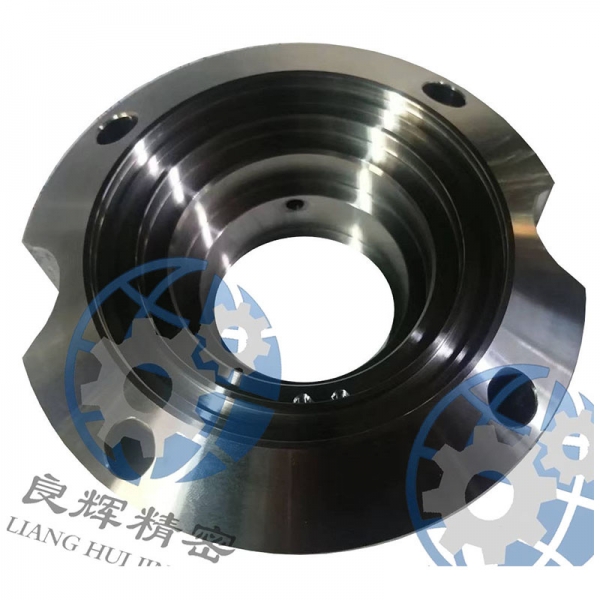

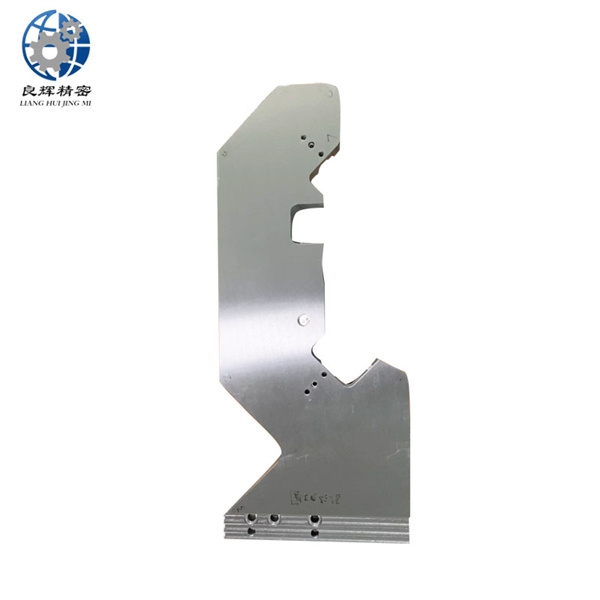

泵體是泵的主要零件之一,起到支撐和固定其他零部件的作用。泵體通常由鑄鐵、鋼鐵、不銹鋼等材料制成,具有一定的強(qiáng)度和剛度,能夠承受泵的工作壓力和溫度。泵體通常具有蝸殼型、螺旋型、離心型等不同結(jié)構(gòu),根據(jù)泵的工作原理和工況選擇不同的泵體結(jié)構(gòu)。

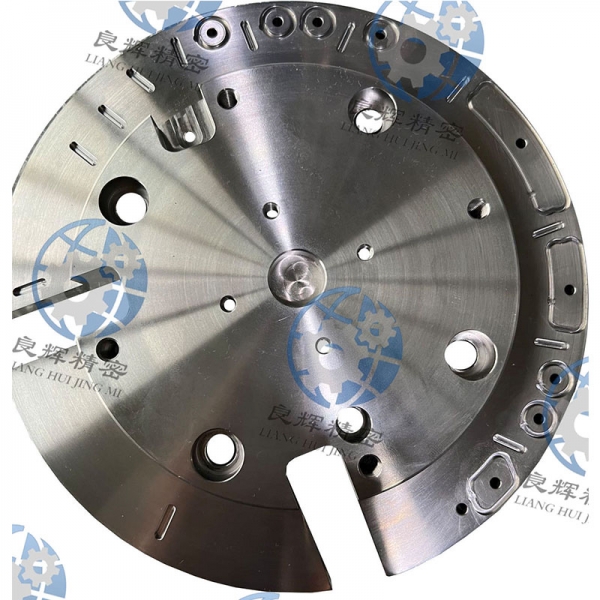

葉輪是泵的核心部件之一,負(fù)責(zé)轉(zhuǎn)動(dòng)并將液體輸送到系統(tǒng)中。葉輪通常由鑄鐵、不銹鋼、高強(qiáng)度塑料等材料制成,具有一定的結(jié)構(gòu)設(shè)計(jì)和表面處理,以提高泵的效率和性能。葉輪的形狀和尺寸根據(jù)泵的類型和工作條件不同而有所區(qū)別,如離心泵的葉輪通常為直葉片或曲葉片,螺桿泵的葉輪為螺旋狀。

軸承是泵的支撐部件之一,承受泵軸的轉(zhuǎn)動(dòng)和徑向負(fù)載,確保泵的穩(wěn)定運(yùn)轉(zhuǎn)和壽命。軸承通常由鋼球、滾柱、滑動(dòng)等方式組成,具有一定的耐磨、抗腐蝕和高溫性能。軸承的選用應(yīng)根據(jù)泵的轉(zhuǎn)速、工作溫度和負(fù)載條件確定,以保證泵的運(yùn)轉(zhuǎn)平穩(wěn)和可靠。

Pump parts used for sealing purposes

Pump parts refer to the components used for maintenance and repair of pump equipment, which play a critical role in the normal operation and performance of the pump. Pump parts are widely used in various industrial fields, including chemical, petroleum, papermaking, power, metallurgy, mining and other industries. There are various types of pump components, including pump body, impeller, bearing, mechanical seal, shaft sleeve, shaft, casing, etc. Dalian Machinery Processing

The pump body is one of the main components of a pump, which plays a role in supporting and fixing other parts. The pump body is usually made of materials such as cast iron, steel, stainless steel, etc., which have a certain strength and stiffness and can withstand the working pressure and temperature of the pump. The pump body usually has different structures such as volute, spiral, centrifugal, etc., and different pump body structures are selected according to the working principle and operating conditions of the pump.

The impeller is one of the core components of a pump, responsible for rotating and delivering liquid into the system. The impeller is usually made of materials such as cast iron, stainless steel, high-strength plastic, etc., with certain structural design and surface treatment to improve the efficiency and performance of the pump. The shape and size of the impeller vary depending on the type and working conditions of the pump. For example, the impeller of a centrifugal pump is usually straight or curved, while the impeller of a screw pump is spiral.

Bearings are one of the supporting components of pumps, which bear the rotation and radial load of the pump shaft, ensuring the stable operation and service life of the pump. Bearings are usually composed of steel balls, rollers, sliding, etc., and have certain wear resistance, corrosion resistance, and high temperature performance. The selection of bearings should be determined based on the pump's speed, operating temperature, and load conditions to ensure smooth and reliable operation of the pump.