用于密封作用的泵用零件

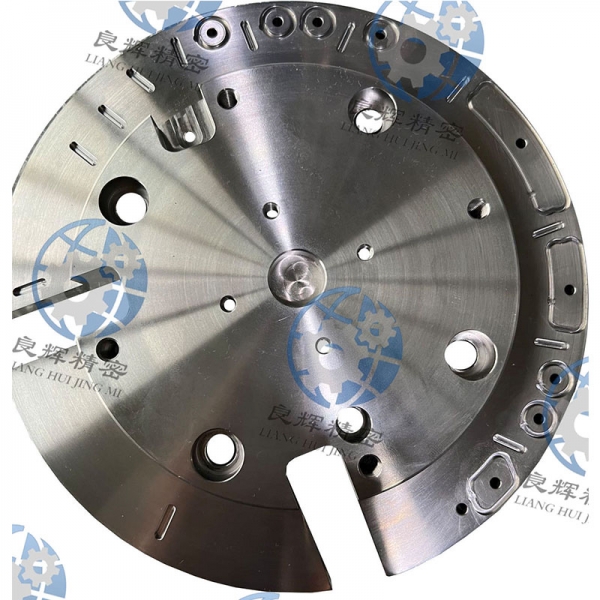

機(jī)械密封是泵的關(guān)鍵部件之一,用于防止泵內(nèi)的液體外泄和泄漏。機(jī)械密封通常由密封環(huán)、密封座、彈簧等部件組成,具有一定的密封性能和耐磨性。機(jī)械密封的選擇應(yīng)根據(jù)泵的介質(zhì)、溫度和壓力確定,以確保泵的安全和高效運(yùn)行。大連機(jī)械加工

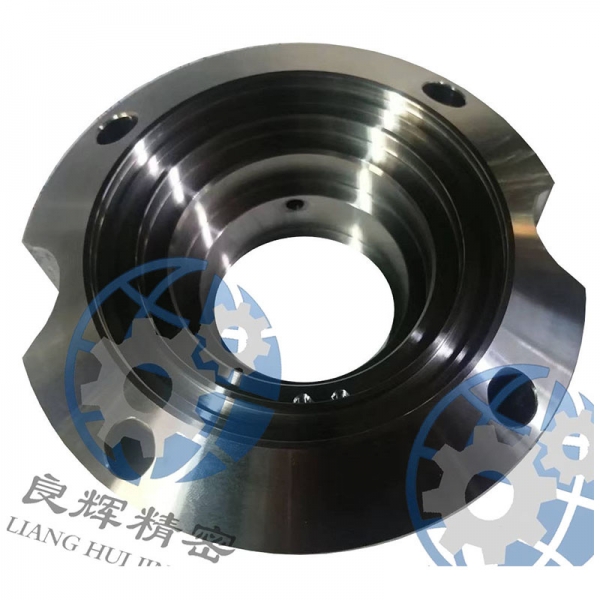

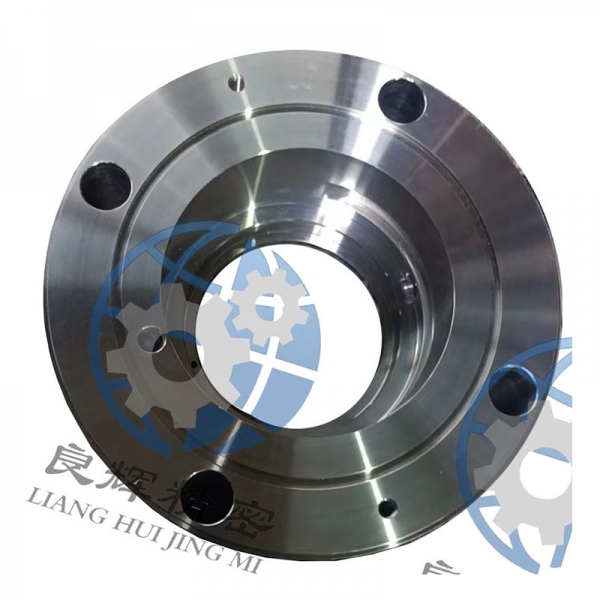

軸套是泵的連接部件之一,安裝在泵體和泵軸之間,起到支撐和封閉作用。軸套通常由銅、鐵、聚四氟乙烯等材料制成,具有一定的耐磨、耐腐蝕和耐高溫性能。軸套的尺寸和形狀應(yīng)與泵的軸孔和密封要求相匹配,以確保泵的運(yùn)轉(zhuǎn)平穩(wěn)和密封可靠。

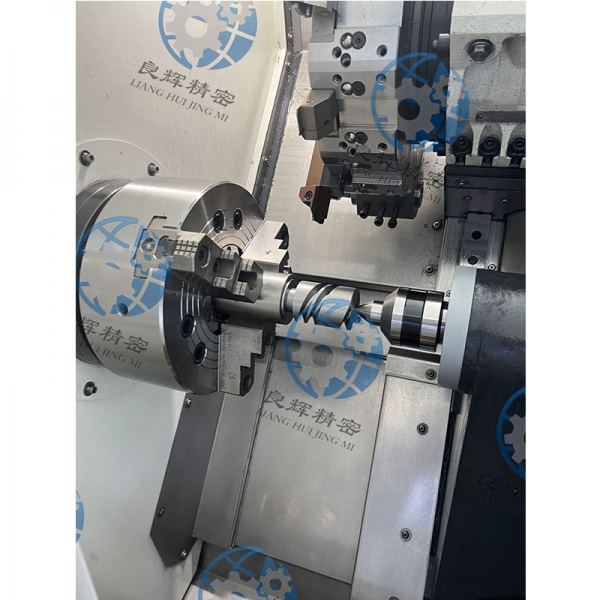

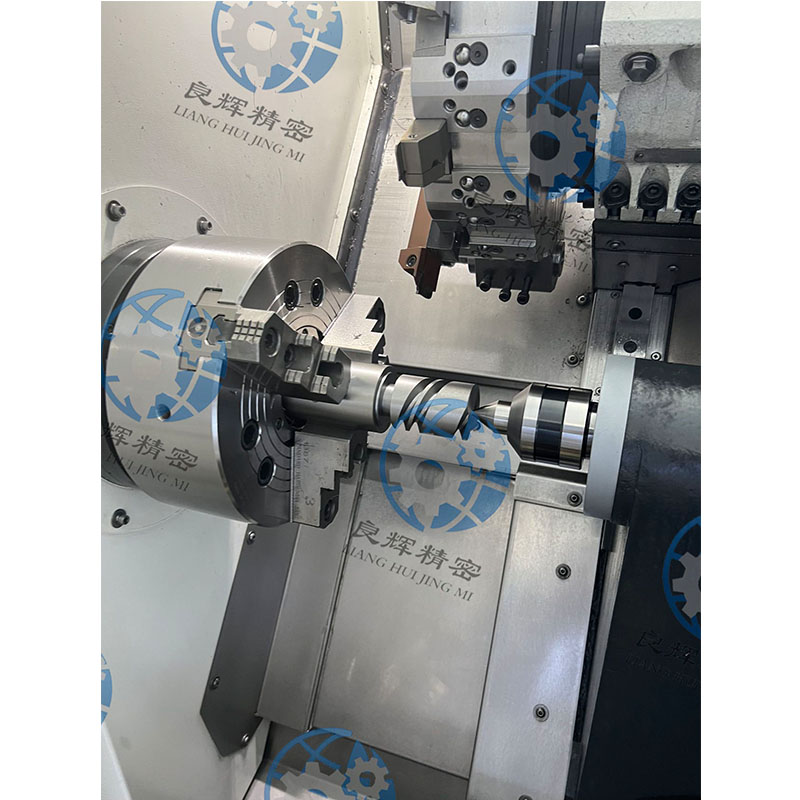

軸是泵的傳動(dòng)部件之一,負(fù)責(zé)轉(zhuǎn)動(dòng)葉輪并將能量傳遞到液體中。軸通常由碳鋼、合金鋼、不銹鋼等材料制成,具有一定的強(qiáng)度和硬度。軸的尺寸和形狀應(yīng)根據(jù)泵的類型和工況確定,以確保泵的傳動(dòng)效率和壽命。

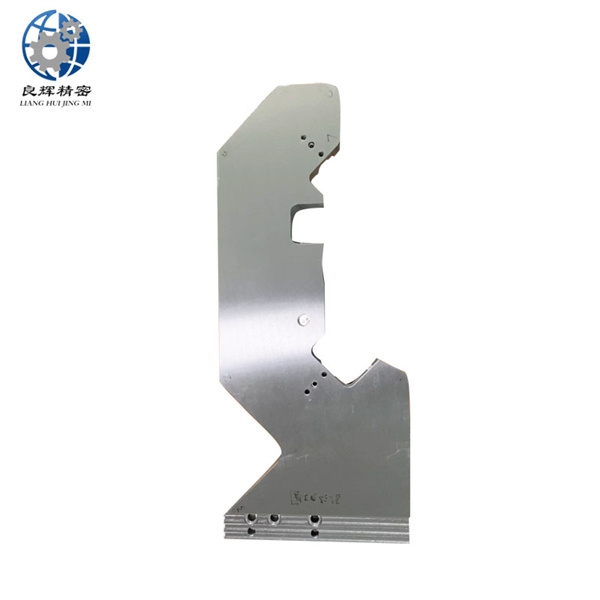

機(jī)殼是泵的外殼部件,起到保護(hù)和支撐泵內(nèi)部零件的作用。機(jī)殼通常由鑄鐵、鋼板、鋁合金等材料制成,具有一定的強(qiáng)度和耐腐蝕性能。機(jī)殼的結(jié)構(gòu)和外形應(yīng)根據(jù)泵的類型和工況設(shè)計(jì),以確保泵的安全運(yùn)行和外觀美觀。

總的來說,泵用零件是泵系統(tǒng)中不可或缺的重要組成部分,對(duì)于泵的正常運(yùn)轉(zhuǎn)和性能發(fā)揮起著關(guān)鍵作用。不同類型的泵需要不同類型的零部件,根據(jù)泵的工作原理和工況選擇合適的零件至關(guān)重要。在泵設(shè)備維護(hù)和維修過程中,及時(shí)更換和維護(hù)泵用零件可以延長泵的使用壽命,提高泵的工作效率和可靠性。因此,泵用零件的選擇和維護(hù)至關(guān)重要,對(duì)于節(jié)約能源、降低成本和保護(hù)環(huán)境具有重要意義。

Pump parts used for sealing purposes

Mechanical seal is one of the key components of a pump, used to prevent liquid leakage and seepage inside the pump. Mechanical seals are usually composed of sealing rings, sealing seats, springs, and other components, which have certain sealing performance and wear resistance. The selection of mechanical seals should be determined based on the medium, temperature, and pressure of the pump to ensure safe and efficient operation of the pump. Dalian Machinery Processing

The shaft sleeve is one of the connecting components of the pump, installed between the pump body and the pump shaft, playing a supporting and sealing role. Shaft sleeves are usually made of materials such as copper, iron, and polytetrafluoroethylene, which have certain wear resistance, corrosion resistance, and high temperature resistance. The size and shape of the shaft sleeve should match the shaft hole and sealing requirements of the pump to ensure smooth operation and reliable sealing of the pump.

The shaft is one of the transmission components of the pump, responsible for rotating the impeller and transferring energy to the liquid. The shaft is usually made of materials such as carbon steel, alloy steel, stainless steel, etc., and has a certain strength and hardness. The size and shape of the shaft should be determined according to the type and operating conditions of the pump to ensure the transmission efficiency and service life of the pump.

The casing is the outer shell component of the pump, which plays a role in protecting and supporting the internal parts of the pump. The casing is usually made of materials such as cast iron, steel plate, aluminum alloy, etc., which have certain strength and corrosion resistance. The structure and appearance of the casing should be designed according to the type and operating conditions of the pump to ensure safe operation and aesthetic appearance of the pump.

Overall, pump components are an indispensable and important part of the pump system, playing a crucial role in the normal operation and performance of the pump. Different types of pumps require different types of components, and it is crucial to choose the appropriate parts based on the working principle and operating conditions of the pump. Timely replacement and maintenance of pump components during pump equipment maintenance and repair can extend the service life of the pump, improve its efficiency and reliability. Therefore, the selection and maintenance of pump components are crucial for energy conservation, cost reduction, and environmental protection.