鋁件面積大,在氧化槽內擺動過大,邊沿和中心部位與溶液的接觸、更新、交換有很大的區別,從而導致氧化膜色彩不一。

解決方法:

氧化時工件擺動的幅度要小,靜處理也可以,但當溶液溫度過低時容易出現地圖狀花斑,顯得不自然。

用鍍鋅鐵絲綁扎氧化件。

解決方法:

鐵絲使用前必須先退除鋅層。

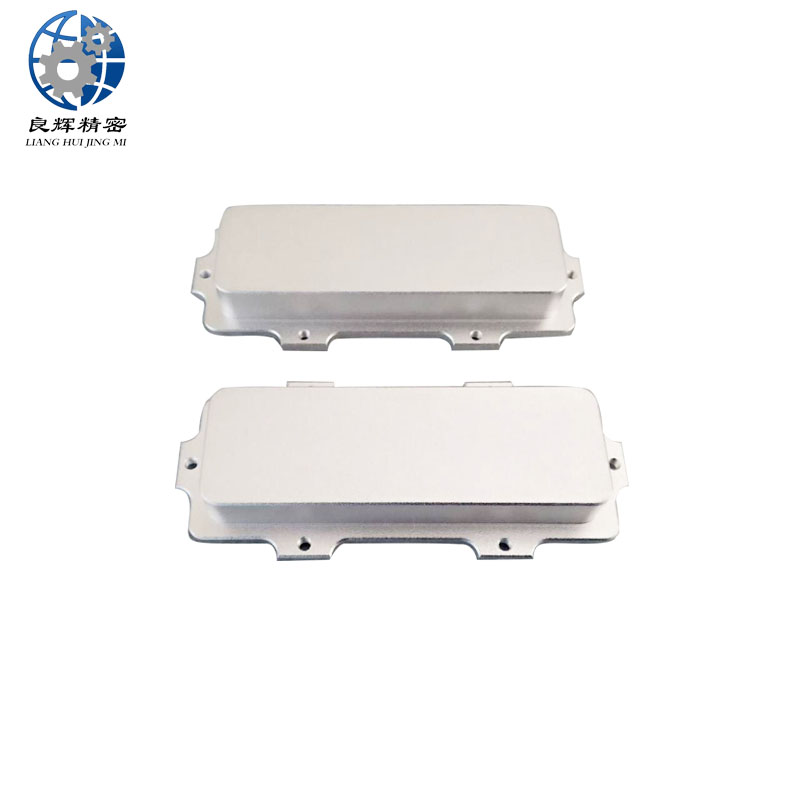

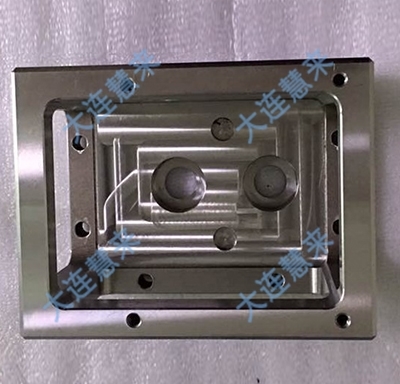

Sandblasting conductive oxidation mechanical CNC precision machining,

The surface of the piece is large and moves greatly in the gasification tank, resulting in significant differences in contact, renewal, and exchange with the solution at the edges and center, leading to inconsistent colors of the oxide film.

resolvent:

The amplitude of workpiece oscillation during oxidation should be small, and static treatment can also be used. However, when the solution temperature is too low, map like flower spots are prone to appear, which appear unnatural.

Tie the oxidized parts with galvanized iron wire.

resolvent:

The zinc layer must be removed before using the wire.